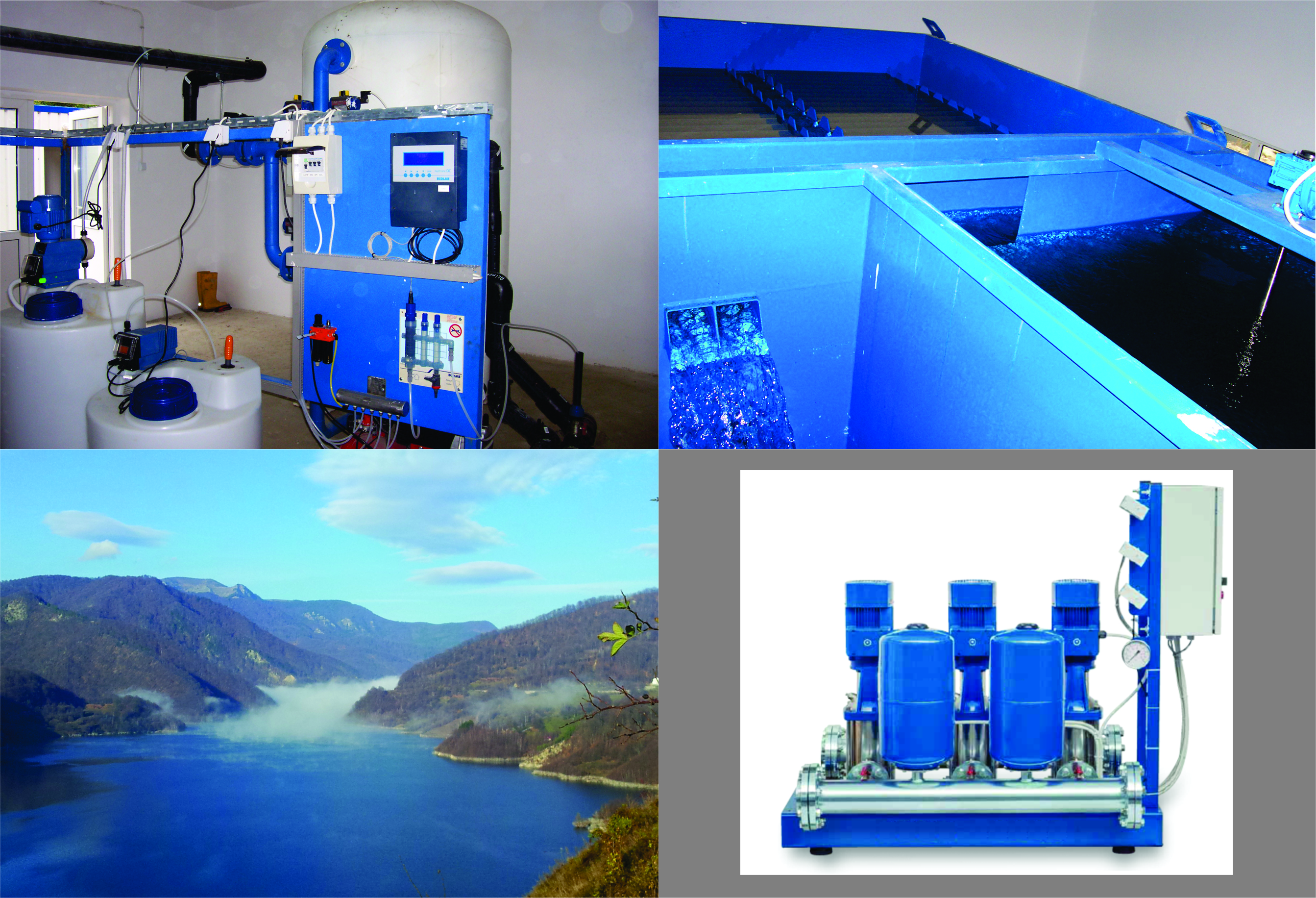

Compact surface water treatment plants can be mounted in container of a building. These equipment are fully automated, they do not need any operating staff, just periodic monitoring.

The components of the plant are the followings:

1. PRE-FILTRATION: mechanical automatic backwashing filter, which eliminates sand and impurities coming in the station;

2. PRE-CHLORINATION: chlorine stocking tank, membrane dosing pump, Woltmann flow meter, dosing system;

3. COAGULATION-FLOTATION: the coagulation- flocculation installation it is used to dose coagulant and flocculent solution. The coagulant or flocculent can be used in granulate form, but also in liquid. The installation it is compound of the followings: stocking tank, electric mixer for dissolving and maturating the coagulant, membrane dosing pump, dosing system (suction lances, aspiration pipes, dosing pipes and dosing injectors).

4. PHASE-SEPARATION– DECANTATION: the phase separation process of raw water (decantation) it is executed in BIPC lamellar settler. This tank is compartmented as follows:

Compartment no. 1 is the reaction compartment for coagulation process. This is being endowed with an electric mixer, which facilitates the coagulation process.

Compartment no. 1 is the reaction compartment for coagulation process. This is being endowed with an electric mixer, which facilitates the coagulation process.5. PUMPING STATION – MULTIMEDIA FILTER ALIMENTATION: the pumping station has the role to pump the decanted water to multimedia filter, also for realizing the backwashing process of the filter. The automatic functioning of the pumps is held out by a local control panel.

The pumping station has the following components:

6. FILTRATION-TURBIDITY REDUCTION: The filtering station has the role to reduce the turbidity of the wastewater by eliminating the impurities and colloidal material. The filters functioning is automated, it does not need operating staff. The equipment can be started by:

7. POST-CHLORINATION– this installation is a fully automated.

It has the following components: chlorine stocking tanks, membrane dosing pumps, dosing systems (aspiration valve, aspiration pipe, dosing pipes, dosing injectors)

8. SLUDGE TREATMENT AND DEWATERING: the sludge which is being settled periodically is being removed and transferred to sludge dewatering equipment.

The installation is being compound out of the followings:

9. AUTOMATION: the plant is totally automated; it does not need operating staff. The automatic function of the station is being realized by a programmable controller.