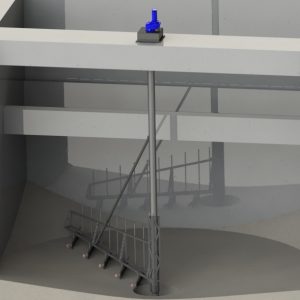

These types of equipments are used in water potabilization industry in sludge thickening process. The types of scraper bridges are mounted in circular tanks, leaning on concrete beam and they are adapted to the tanks geometry.

These types of equipments are used in water potabilization industry in sludge thickening process. The types of scraper bridges are mounted in circular tanks, leaning on concrete beam and they are adapted to the tanks geometry.

The bridge is designed to collect and transfer the settled sludge on the bottom of the tank—the bridge will transfer the sludge in the central of the tank where the evacuation hopper is.

The action of the bridge is made by a geared motor.

The bridges moving speed is designed so it does not disturb the settled sludge on the bottom of the tank. In the same time the speed of movement ensures maximum efficiency of the cleaning of the bottom: the sludge does not have time to thicken on the bottom of the tank.

The bridges moving speed is designed so it does not disturb the settled sludge on the bottom of the tank. In the same time the speed of movement ensures maximum efficiency of the cleaning of the bottom: the sludge does not have time to thicken on the bottom of the tank.

The scraper system of the bridge it is made out of stainless steel and it is designed to cover the whole surface of the bottom of the tank and in the same time to ensure a uniform clearing of the bottom. The cleared water is being overflowed in the periphery weir.

All the submerged parts of the equipment are made out of SS 1.4301 (optional SS 1.4401), everything else is made out of hot galvanized carbon steel (at request SS)

The bridge is delivered with its own control panel, which assures the automating functions of the bridge, the speed of the bridge is being set by a frequency converter.

The bridge does not require any operating staff.

Our company designs, manufactures, delivers and mounts different type and dimension scraper bridges.