These equipments are basically made out of a trough (SS 1.4301, optional SS 1.4401) in which there is mounted a screw. The trough has one or two feeding inlet and one evacuation outlet for the retained material. The helicoidal conveyors are made to transport different materials, such as: granulate, solids, retained materials from the screens, sludge, dewatered sludge, lime etc.

These equipments are basically made out of a trough (SS 1.4301, optional SS 1.4401) in which there is mounted a screw. The trough has one or two feeding inlet and one evacuation outlet for the retained material. The helicoidal conveyors are made to transport different materials, such as: granulate, solids, retained materials from the screens, sludge, dewatered sludge, lime etc.

Depending on usage, these conveyors can be:

The screw conveyors are compact closed equipment, to eliminate any odors; they can also be coupled to the ventilation system.

The helicoidal screw conveyors that are used to transport lime, are totally sealed to the lime bin. The speed of the geared motor is various to regulate the flow.

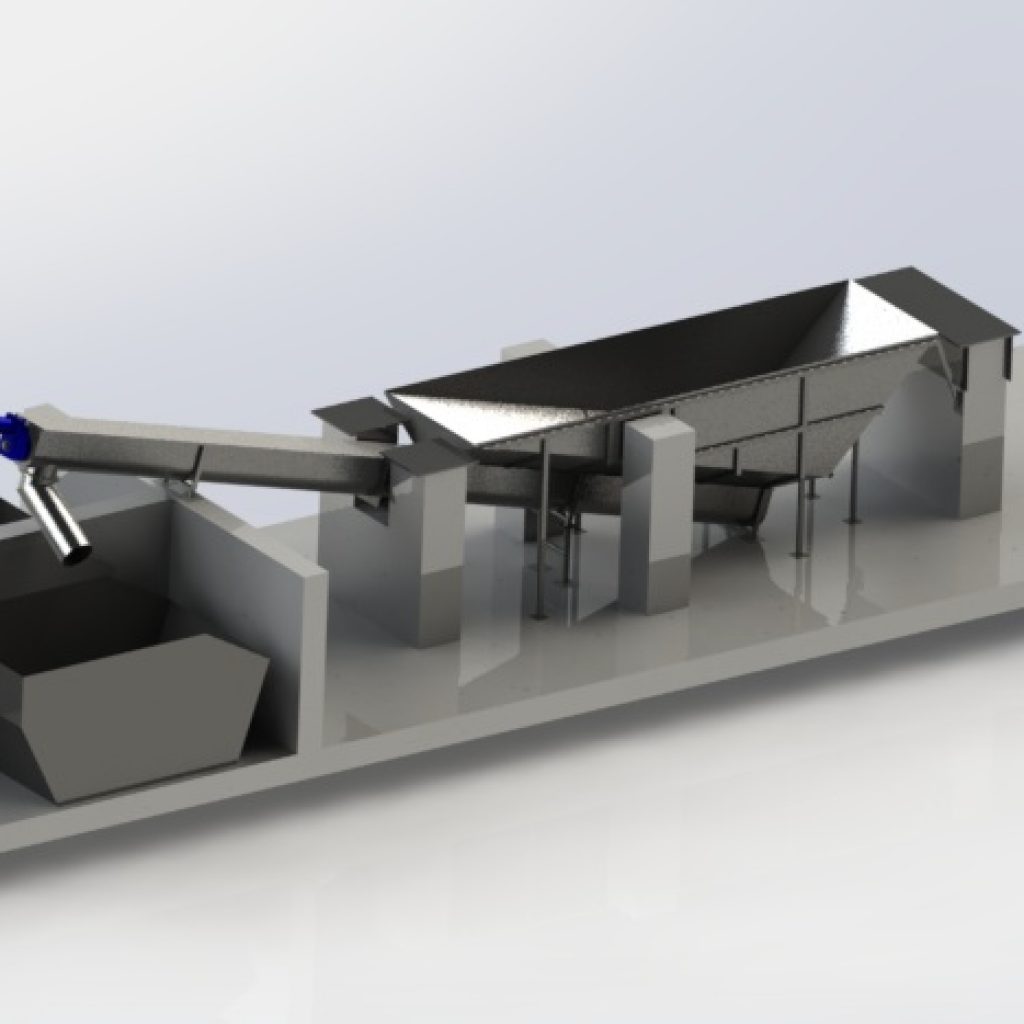

The band conveyors are used to transport solid materials horizontally or under angle 5 -25º (for ex. solids retained by the fine and coarse screens, thickened sludge, dewatered sludge etc.). The band conveyor can be provided with an inlet trough and one movable outlet trough (to left or right).

The dimensions that define the length and width of the band are variable; this is the reason why it is designed depending on the place of mounting and natural of the material that will be transported.

Capacity of the conveyor: 0,2 m3/h- 1 m3/h.

The length of the conveyor: 2 -20 m (depending on request)

Construction material: carbon steel with anticorrosion protection, for the structure; inserted rubber- for the transporting band.

Banda poate fi prevazuta cu jgheab de alimentare sau cu posibilitatea de a fi montata la un jgheab de alimentare si cu jgheab de descarcare dirijabil, fie pe stanga , fie pe dreapta.

Dimensiunile care definesc lungimea si latimea benzii sunt variabile din acest motiv se proiecteaza in functie de locul montarii si de natutra materialului care va fi transportat.