The sludge treatment is used in the wastewater treatment plants, by reducing significantly the quantity of water and simultaneously increasing the DM in the sludge content. This process starts with the sludge thickening process and then dewatering process.

The difference between these two processes is that in the thickening process the water content in the mixture is cca. 90- 99%. In this process the sludge is being mixed with the right amount of polyelectrolyte. The mixing and the contact time is setup to help the flocculation process. After this the flocculated sludge will be introduced in thickening or dewatering system.

There are 3 ways to thickening sludge: flotation, gravitational (settling) or by the centrifugal power.

This equipment can process a large amount of sludge with relatively small power consumption. While the drum is making a rotating movement the water is being evacuated on the opposite side of the inlet. The excess water is drained thru the material and collected in the trough, from where it is being evacuated.

The concentration of the sludge can be set up by the dosage of this into the equipment, the inclination and the speed of the equipment. The solid phase- with cca. 6% DM content- is evacuated gravitational and pumped towards the dewatering system. The small speed assures a fine sludge treatment.

The installation is automated; it does not need any operating staff.

This equipment can be used both for sludge thickening and dewatering processes. They are used especially in small and medium wastewater treatment plants.

Its functioning is similar to the centrifugal decanter, but with significantly less power consumption.

The thickening, as well the dewatering process has many steps, such as:

Using this equipment the dewatered sludge DM content can be up to 18%.

It is important to mention that the type of belt cloth is selected according to sludge type. The optimum selection of material can be reached if the sludge is being tested.

The belt press function is automatic, can be equipped with belt conveyor or a helicoidal screw conveyor to dewatered sludge discharge.

It is easy to maintain it by cleaning the belt and drums surfaces.

According to the type of the sludge the installation can be delivered with sludge thickener, flocculation reactor or static mixer.

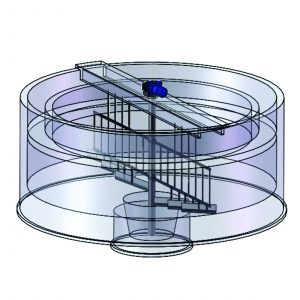

The thickening process can be worked out gravitational by radial settler made by concrete. This is equipped with a scraper bridge which has the role to ensure a slow mixed up, facilitating the settling process and helps eliminating gases from fermentation.

Gravitational thickeners are used in case of low and medium capacity of wastewater treatment plants (250 000 PE), where the capacity of sludge is appox. 40 m3/day.

The percentage of DM content after gravitational dewatering can reach 2.5-4 %.